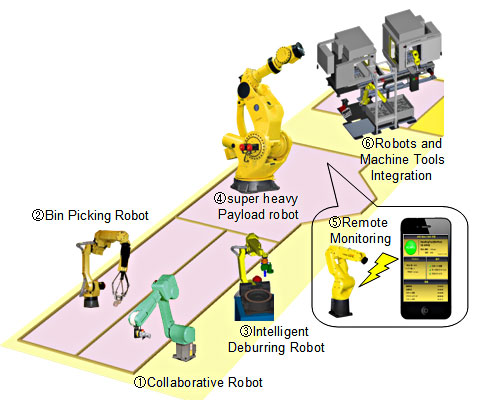

FANUC will exhibit the Green Collaborative Robot designed to be operated safely in the presence of human operators without any safety fences.

This robot must strongly support a new generation of manufacturing with its innovative functions.

Please experience how innovative they are.

FANUC will also show many robot systems with newest robot technologies.

They can realize a factory automation that used to be difficult to eliminate human operators in the past.

DCS (Dual Check Safety) function realizing a robot system without any safety fences and Bin Picking Robot eliminating parts arrangement can give a higher efficiency to factories.

Intelligent Deburring Robot automatically adjusting its trajectory by a vision sensor can realize a higher deburring quality.

Zero Downtime function can provide a higher reliable manufacturing system through remote monitoring, preventive maintenance and problem prediction.

Integration function between FANUC CNC and FANUC robot can provide more flexibilities to their manufacturing process.

FANUC robots will provide "'reliable", "predictable" and "'easy to repair" functions to realize a higher productivity of factories.

A demonstration of the Green Collaborative Robot operated safely in the presence of human operators

operated safely in the presence of human operators

A demonstration of DCS (Dual Check Safety) function realizing a robot system without the need for safety fence

You can experience the high sensitive reaction of these robots to the human contact or approach.

A demonstration of Bin Picking the actual work from the bulk

You can see that the robot detects the position and direction of the work-piece pilled up in the bulk in an instant and pick it up rapidly and work efficiently.

You can experience the actual picking by Bin Picking Gripper which can pick the non-ferrous casts, which vacuum pad or magnet hand can not grip.

which can pick the non-ferrous casts, which vacuum pad or magnet hand can not grip.

ROBOGUIDE specifies edges to deburr on CAD data, iRVision detects edges on real work-piece with position offset and shape difference, then generates Robot's trajectory for deburring automatically

You can see the loading/unloading of castings by the robot with 1,350kg payload.

Using vision sensors, the precise positioning of very big robot becomes possible.

Robot status can be monitored from cell phones, and diagnostic/prevention is possible by Zero Down Time function . You can experience the actual operation of the latest functions of ROBOGUIDE, No 1 easy-to-use simulation software.

. You can experience the actual operation of the latest functions of ROBOGUIDE, No 1 easy-to-use simulation software.

Robot can open/close the servo door of ROBODRILL so that very fast work-piece exchange is possible.

Using robot teach pendant, machine tool correction can be input.