(October 23, 2018) Updated for more information.

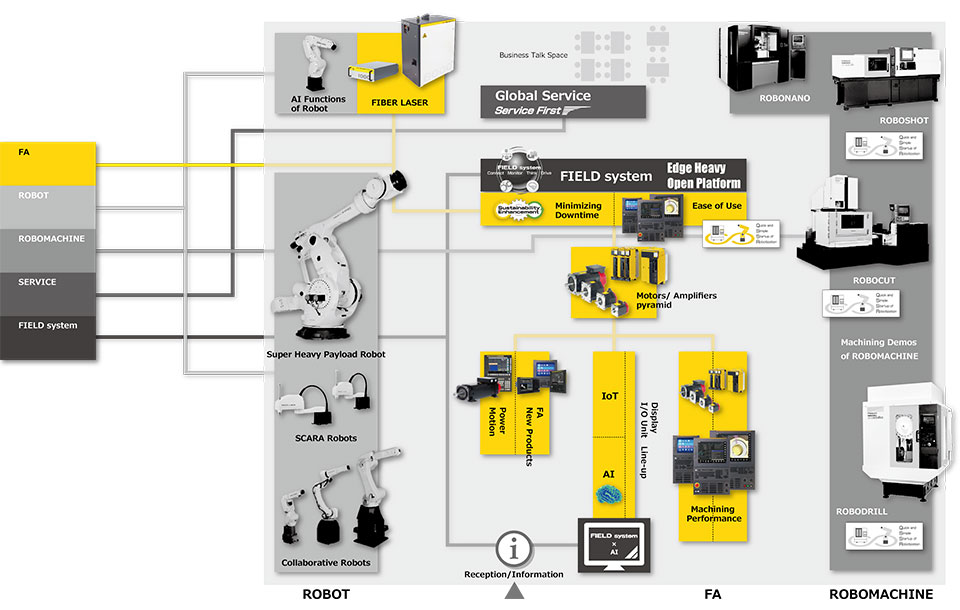

FANUC FA products will contribute to improving productivity of the manufacturing site worldwide with three development themes; “Machining Performance”, “Ease of Use”, and “Minimizing Downtime”.

FANUC will contribute for higher performance of machines by aiming to “Better Surface Quality”, “Higher Precision Machining Shape”, and “Reducing Cycle Time”.

FANUC will provide products for various purposes that have the features such as “Easy Start-up and Adjustment of Machines”, “Integral Support of Job”, and “Adaptable to Various Machines”.

FANUC will contribute to establish durable FA system which represented in the word “Reliable”, “Predictable”, and “Easy to Repair”, by the functions that support “High Reliability”, “Preventive Maintenance”, and “Shorter Mean Time To Repair”.

In our booth, you can experience the advanced features of our FA products, which are arranged in the categories of these three themes. For AI and IoT, we have exhibited "AI function for FA" and "IoT for FA" corner set up.

Please visit FANUC FA corner to realize that FANUC FA products can strongly support your product manufacturing.

0i-F Plus is new model which line up high-end models equipped with iHMI. 0i-F Plus achieves higher machining performance and ease of use by improving the basic functions.

Performance required for PC function has been improved. By allowing the PC body to be installed separately, the flexibility of designing the control panel such as a thin control panel has expanded.

Applications using image processing for machine tools can be created. CNC Vision Function provides a system that can directly call a vision program that combines image processing functions from a CNC machining program directly.

It compensates for deterioration of accuracy due to temperature change of machine tool. The displacement is estimated the from the current temperature using the thermal displacement model obtained by machine learning.

The machine learning automatically optimizes more advanced control (AI feedforward).

It achieves high precision by avoiding machine vibration.

AI Spindle Monitor calculates anomaly score and do monitoring failures of spindles by machine learning. It helps to reduce downtime of machine tools due to sudden failures.

MT-LINKi is a PC software to connect with machines in factory via Ethernet and to collect, manage and visualize various machine data.

MT-LINKi can collect data from not only machine tools with FANUC CNC but also various devices that have OPC or MTConnect communication function and it contributes to computerization of factory.

Servo Learning Oscillation achieves secure chip shredding in turning.

5-axis machining functions will achieve high-speed and smooth machining. The functions to improve usability of 5-axis machining tool are also provided.

Fine Surface Technology is the CNC and SERVO technologies for fine surface machining.

It supports to improve fine surface machining for die-mold.

Fast Cycle-time Technology is the CNC and SERVO technologies for cycle time reduction. It supports to improve productivity of the machine tool.

This function achieves high speed, high precision and high quality cutting with optimized control in real time according to change of machine conditions such as load, temperature or position, etc.

High power spindle by ultra-high power spindle amplifier with SiC power device and PWM converter takes advantage of high-speed heavy cutting.

QSSR provides functions to connect machine tool and robot easily and supports the start up of automatic work exchange system by robot.

iHMI integrally supports necessary operations at on-site job and provides necessary functions for not only machine operations but also each process of ‘Planning’, ‘Machining’ and ‘Improvement’.

FANUC PICTURE is a customization tool for creating CNC screens.

You can create custom screens easily by combining basic parts.

Additionally, you can create more flexibility screens by using the general scripts.

Leakage detection, brake check and capacitor check functions contribute to preventive maintenance of motor and amplifier and make minimizing downtime.

The structure for quick replacement and the failure prediction of fan motor can be achieved.

Multi-axis high response function up to 24 axes and position/speed/torque/pressure control are enabled to apply for various industrial machines. This CNC is also available for injection molding machine.

FANUC SERVO MOTOR can be driven with Customer's controller. Various interfaces with controllers are available.

All kinds of motors and amplifiers which are included new SERVO MOTOR with Battery-less PULSECODER, Synchronous SPINDLE MOTOR are exhibited.

SERVO SIZER is PC software which supports to select suitable motors and amplifiers. It is also available the latest information about motors and amplifiers.

FANUC provides CNC, SERVO MOTOR, and LASER as one stop solution, these achieve high-speed high-synchronicity required for Fly-cut and Laser marking.

Standard CNC (Series 30i/31i/32i-B) can also be applied to LASER processing, enabling easy realization of LASER hybrid machines.