(October 19, 2018) Updated for more information.

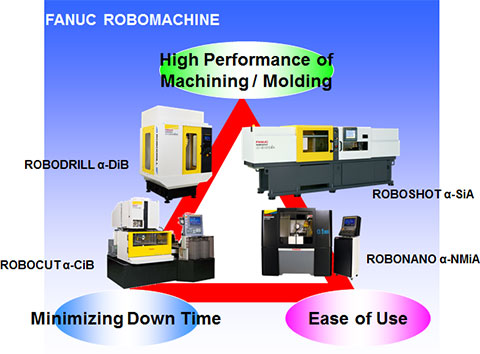

FANUC ROBOMACHINE using latest FANUC CNC and Servo technology will contribute your productivity-up by “High Performance of Machining and Molding”, “Ease of Use” and “Minimizing Down Time” as essential technology components for producer's machine.

High performance of basic specification like as high-speed, high-accuracy and high-power is very important for your productivity. FANUC ROBOMACHINE achieves stable machining / molding for uniformly high-quality products and enable to support for wider range of application in addition to high performance of basic specification.

Usability of machines is indispensable to productivity-up. FANUC ROBOMACHINE has not only excellent user-Interface with iHMI and high expandability, but also simple integration with FANUC Robot in order to automate machining / molding process easily.

Unexpected machine down-time affects your productivity seriously. FANUC ROBOMACHINE will increase your machine sustainability by functions of being “reliable”, “predictable” and “easy to repair”.

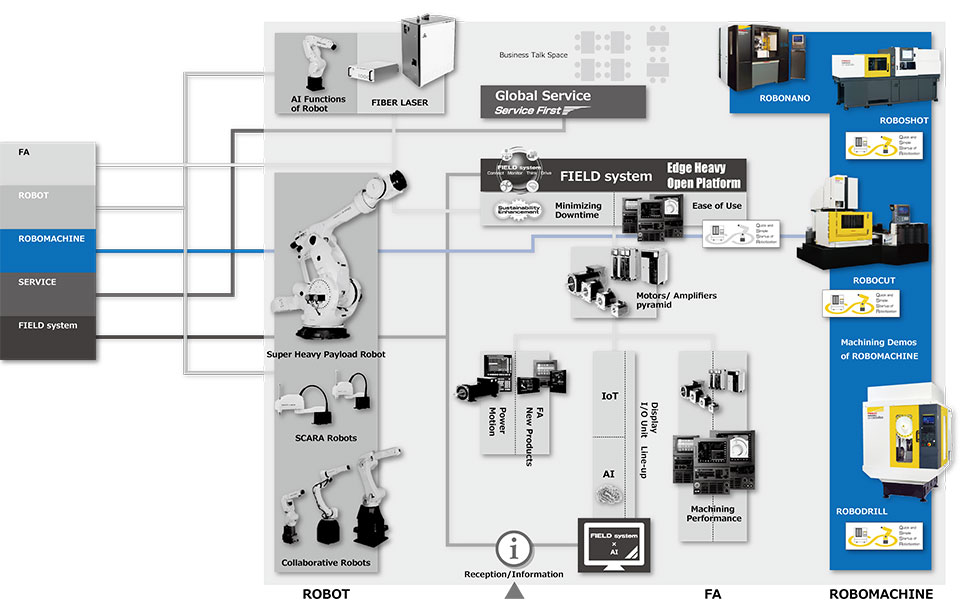

At FANUC booth, in addition to the machining / molding demonstrations by the latest ROBOMACHINEs, FANUC proposes “Quick & Simple Startup of Robotization” to support automation and “IoT Solutions” to promote networking for production site. Please visit FANUC booth and see the latest FANUC ROBOMACHINE technology !

High-cycle machining by high acceleration spindle, servo turret and DDR-TiB is demonstrated. Higher precision is achieved by the improvement of AI thermal displacement compensation.

High-speed profile machining and high-precision multi-angle machining of aluminum block are demonstrated. See the high-efficiency machining more than 2,000 cc/min and excellent chip evacuation.

High-efficiency machining by high torque spindle and deep hole drilling by 7MPa CT coolant of steel block (S50C) are demonstrated. See the “Bari-bari” machining by high power motor and high rigidity mechanism.

High-speed and high-efficiency machining by high speed spindle and 2-axis DD rotary table is demonstrated. FANUC proposes ROBODRILL-QSSR to realize automation easily.

Fine surface machining by high speed spindle and the latest CNC & Servo technology is demonstrated. FANUC proposes automation system with Collaborative robot by ROBODRILL-QSSR.

Productivity is enhanced by real time monitoring the operation condition of ROBODRILLs.

High-quality cutting of PCD tool is demonstrated with the rotary table FANUC ROBOCUT CCR and FANUC original PCD power supply. FANUC proposes “Quick & Simple Startup Robotization” (ROBOCUT-QSSR) to build automation easily.

With a large machine, X800 x Y600mm stroke, high-precision cutting of turbine disc is demonstrated. Robocut realizes stable cutting by AI thermal displacement compensation function, also realizes sustainability by higher-reliable AWF3.

Productivity is enhanced by real time monitoring the operation condition of ROBOCUTs.

Stable molding of precision connector with automated inspection and arrangement system is demonstrated. FANUC proposes “Quick & Simple Startup Robotization” (ROBOSHOT-QSSR) to build automation easily.

Production and quality information management tool adaptive to the globalization and magnification of molding factory. Productivity is enhanced by real time monitoring the operation condition of ROBOSHOTs.

Mirror finishing of automobile headlamp mold without polishing is demonstrated. And the smart measurement package which improved the usability of ultra-precision machine is exhibited.