Fast and accurate CNC simulator

About CNC GUIDE 2

Three features of CNC GUIDE 2

Servo Model

Reproduces mechanical characteristics of each axis in addition to CNC and servo control

Up to 20x faster simulation

Significant improvement in work efficiency through reduced time for test runs, etc.

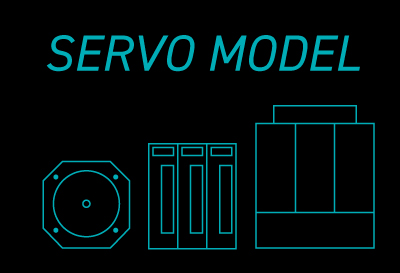

Digitally accurate CNC simulation

CNC GUIDE 2 is a PC software that allows you to digitally simulate CNC without occupying the machine.

It faithfully reproduces CNC motions such as acceleration/deceleration and smoothing functions,

and accurately simulates tool trajectories and machining times.

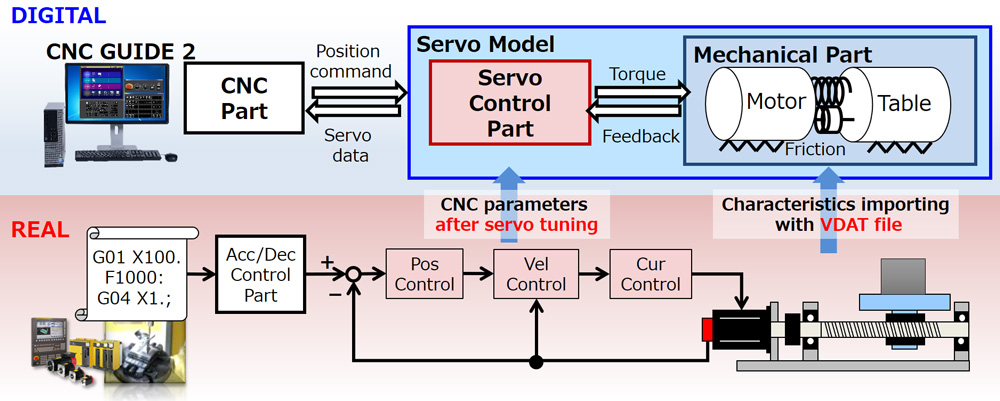

Servo Model

Servo Model digitally models servo control and machine characteristics of each axis.

As in the real world, it consists of a Servo Control Part and a Machanical Part.

Servo Model is a technology that brings

the real and the digital (simulation) closer together.

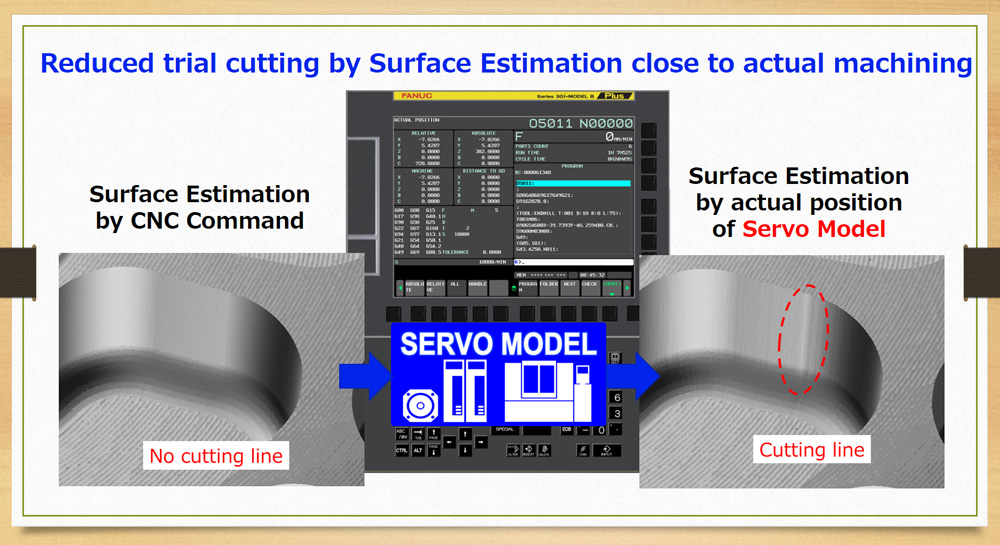

What we can do with Servo Model

Servo Model can output a virtual position that reproduces the servo's control

and vibration caused by acceleration and deceleration.

Therefore, the following things are possible.

- Digitally adjust parameters such as acceleration/deceleration

- Simulation of more realistic machined surfaces and machine movements

- Accurate machining time prediction

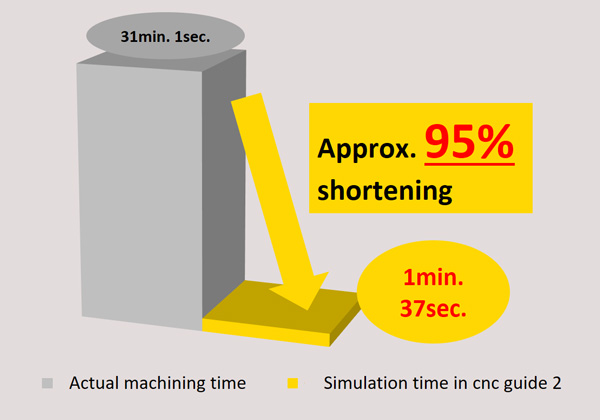

High-speed simulation

Simulations can be run at high speed up to 20x faster.

Program running time is shortened, and the work time required for trial run, parameter adjustment,

and confirmation of machined surface quality can be expected to be reduced.

Example of high-speed execution

High-speed simulation in about 95% less time than actual machining time (Processing speed about 20x faster)

※In the case of a machining program assuming mold finishing

(approx. 80,000 lines, average block length approx. 0.1 mm, F1500)