Tool to verify accurate machine operation

About CNC Reflection Studio

Accurate machine operation checks

CNC Reflection Studio (CNCRS) is a PC software that allows you

to digitally verify machine operation when executing a machining program.

Since no actual machine is used, CNC Reflection Studio offers the following advantages

Secure and fast on digital

Machine operation Simulation

Without occupying actual machine

Check machining program

Due to incorrect machining programs

and tool settings

Prevent machine damage

Simulate machine movements

Machine simulation with accurate CNC and servo control

By executing machining programs with CNC Guide 2, including Servo Model,

actual CNC and servo-controlled operations can be accurately reproduced.

Accurate

G-code analysis

Any G-code program, including

canned cycle commands,

can be analyzed equivalently

to actual CNC.

Accurate

tool path & run time

Even CNC and servo control

is reproduced to calculate

tool path and execution time.

Difference from General Simulation

Simulation using CNC Guide 2 with Servo Model accurately reproduces CNC and servo control,

such as deceleration to avoid shocks at corners and acceleration to command speed.

General Simulation

All tool paths move at a constant speed

Simulation in CNCRS using CNC Guide 2 including Servo Model

This simulation runs at the speed at which the CNC/servo control is reproduced

Accurate and easy-to-cause interference checking

Safe and fast collision check is possible digitally. By performing interference checks prior to actual machining,

machine damage due to errors in machining programs or tool settings can be prevented.

Since information on the block of the machining program where interference occurred is logged,

the cause of interference can be easily identified.

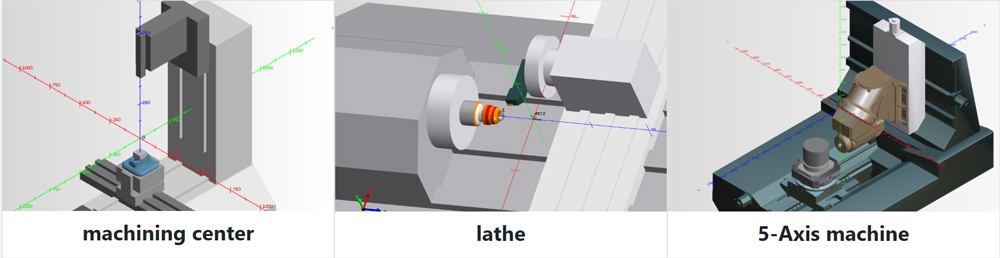

Compatible with a wide range of machine configurations

Machine models can be created using the included software MachineBuilder.

(Created by machine manufacturer based on CAD model of machine)