Tool for checking machined surface quality

About Surface Estimation

Accurate digital confirmation of surface quality

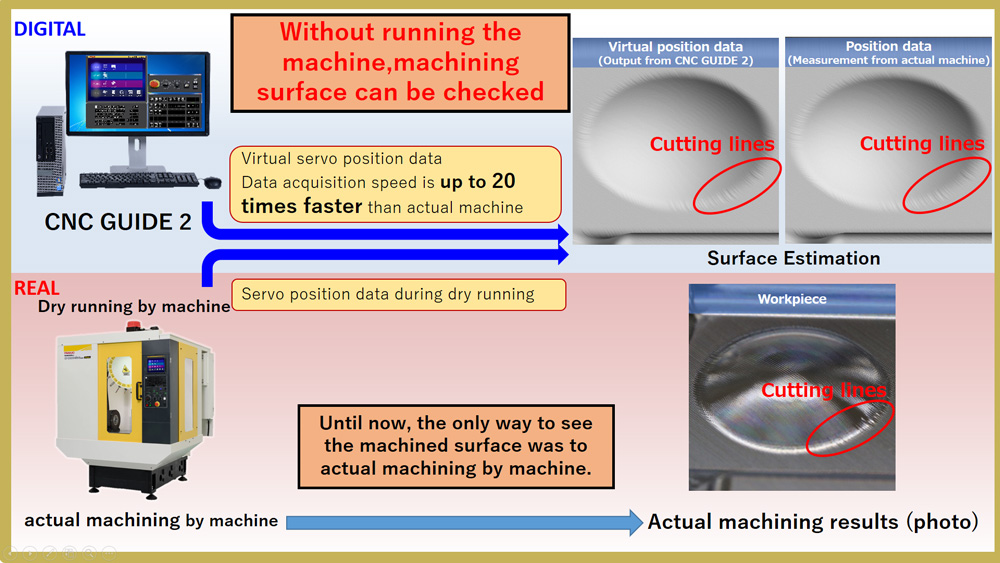

Surface Estimation is PC software that allows you to check machined surfaces digitally, close to the actual machining results.

Machine not occupied

Shorter

working time

Reduce

materials costs

Accurately confirm machined surface quality without actual machining

The machined surface can be accurately checked using the CNC Guide 2 or the position data of each axis obtained by dry running.

Seamless machined surface quality improvement work

Whenever you modify the machining program or parameters, you can immediately check the effect of the modification by Surface Estimation.

Seamless machined surface quality improvement work can be performed digitally.

Streamlining machined surface improvement work

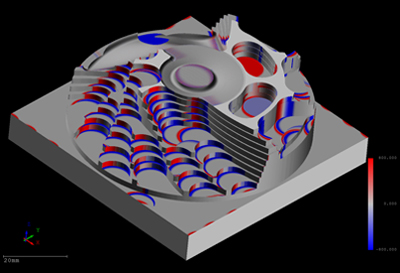

It supports machining surface improvement operations by displaying information that affects surface quality, such as tool acceleration, shape error, and trajectory error, on the machined surface.

Identified problems

easily

Visual surface analysis

Various Analysis Functions

Display of tool speed and acceleration

Displays tool speed and acceleration information in different colors, It is useful for predicting where problems may occur on the machined surface and identifying the cause of the problem.

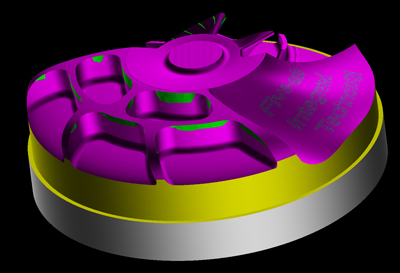

Color-coded by tool

Color-coded display of areas cut by each tool. It is possible to identify which tool or process caused the machined surface defect.

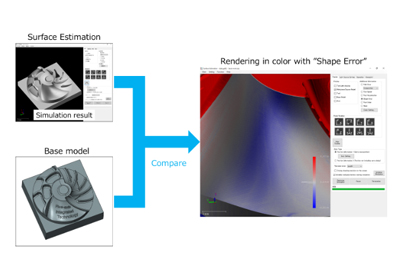

Comparison with Geometry Model

Simulation results can be compared with geometry data to visualize errors compared to the reference model.

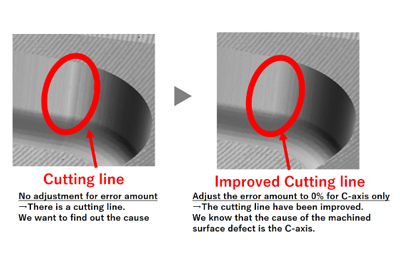

Identifying the axis to be adjusted

When the locus error amount is large, it is possible to estimate the machined surface by adjusting the amount of locus error for each axis. It is easy to identify which axis is the cause of machining defects.

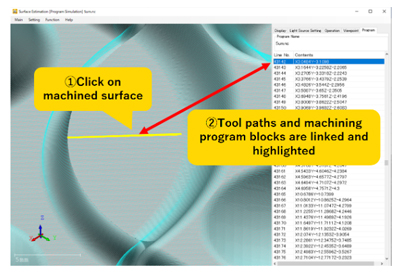

Display of tool locus

Tool paths that cut the machined surface, as well as machining program blocks corresponding to the tool paths, can be identified.