Integrated Environment of FANUC Smart Digital Twin®

About Smart Digital Twin Manager

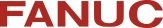

Easy execution of simulations

With one click, you can execute each application of FANUC Smart Digital Twin® to obtain cycle time and the surface quality of the workpiece after machining. Since you can also change simulation conditions on the Smart Digital Twin Manager screen, it's easy to perform re-simulations with altered conditions.

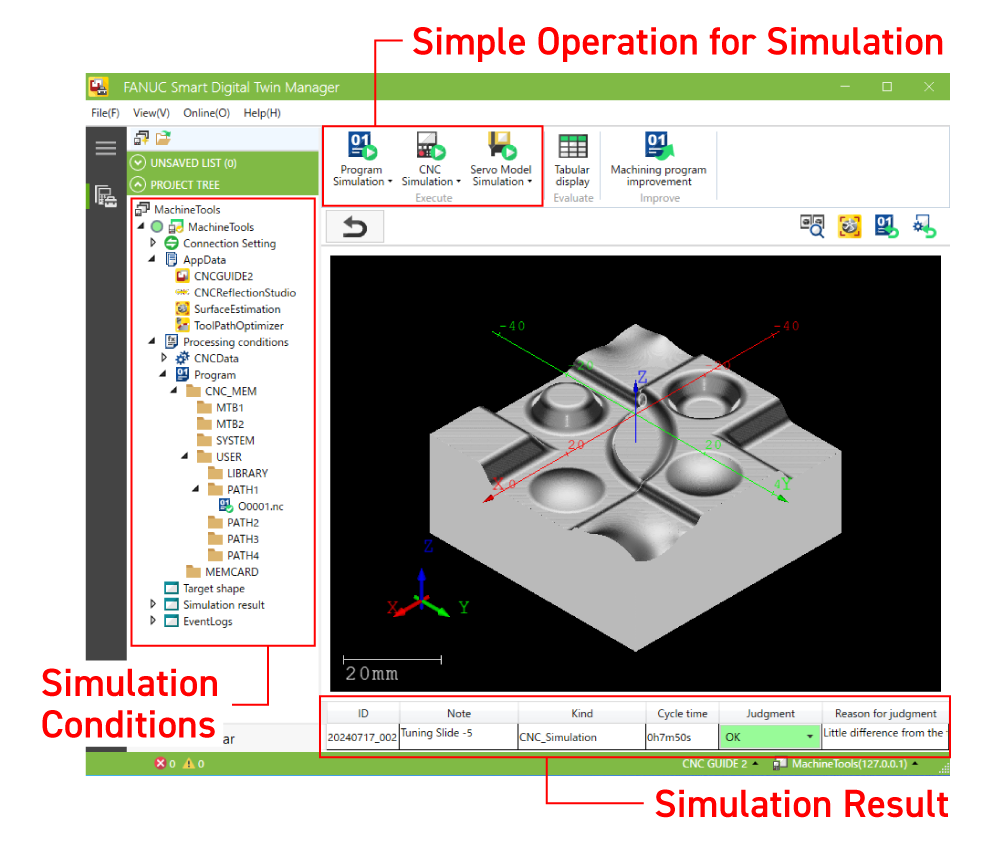

Simulation Result Management

The three simulation results (program, CNC, servo) assist in identifying the causes of machining problems.

If all simulation results are OK but the actual machining results are defective, you can determine that factors not included in the simulation, such as tool vibration or wear, are the cause.

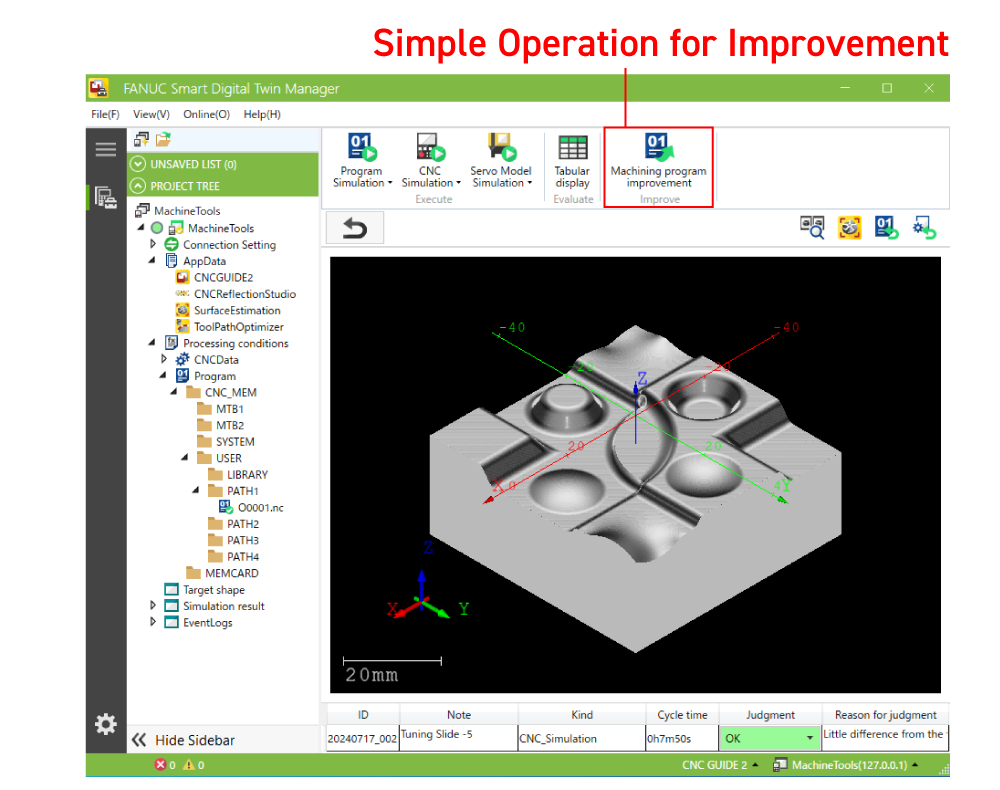

Machining Process Improvement

If there is a problem with the machining program, you can easily optimize it using the Tool Path Optimizer with simple operations.

By performing a re-simulation with the optimized machining program, you can immediately confirm the improvement effects.