Predictive Maintenance Software for

CNC Machine Tools

AI Servo Monitor

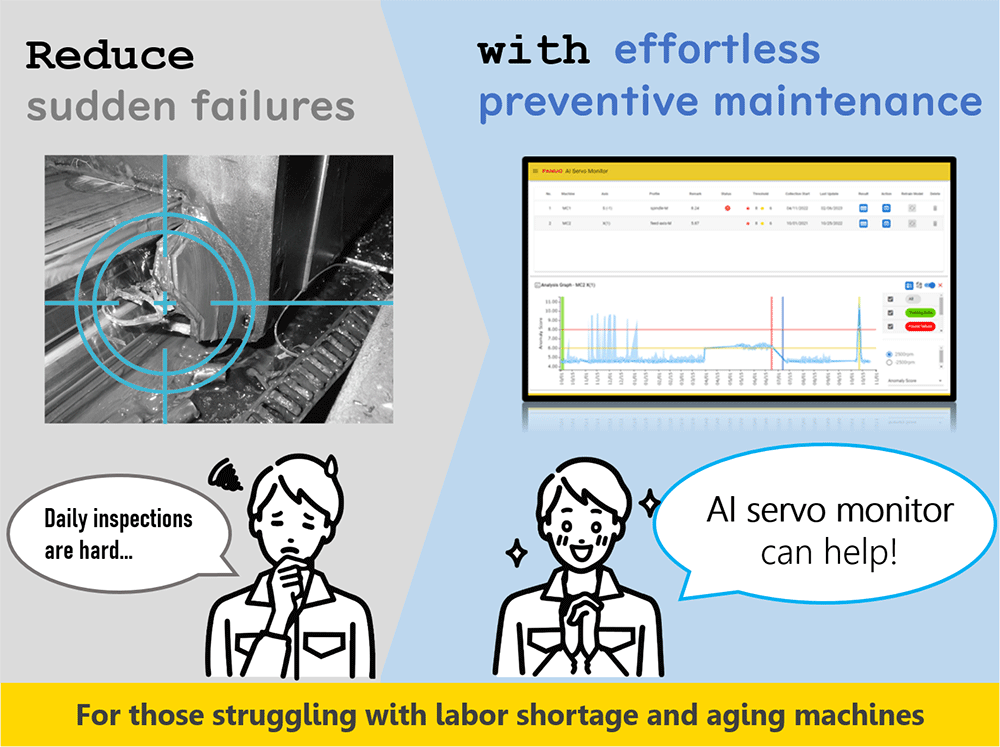

Struggling with preventive maintenance of Your Machine Tools?

For those who are struggling with labor shortages and aging equipment, we have a proposal: effortless preventive maintenance.

The software "AI Servo Monitor" helps with preventive maintenance by detecting early signs of drive system failures in equipment.

View Table of Contents

- Struggling with preventive maintenance of Your Machine Tools?

- Effortless Preventive Maintenance

- How to Use AI Servo Monitor

- Reasons Why AI Servo Monitor is Easy to Start

- Equipment Compatible with AI Servo Monitor

- Comparison with Other Maintenance Software

- How to Start Using AI Servo Monitor

- AI Servo Monitor Support

- Frequently Asked Questions

- Learn More About AI Servo Monitor

Effortless Preventive Maintenance

"Effortless Preventive Maintenance" is a maintenance system that utilizes AI servo monitors to automatically detect early signs of equipment failure and enables efficient maintenance.

This approach makes maintenance easy to start, easy to understand, and easy to continue, thus reducing the burden on on-site personnel.

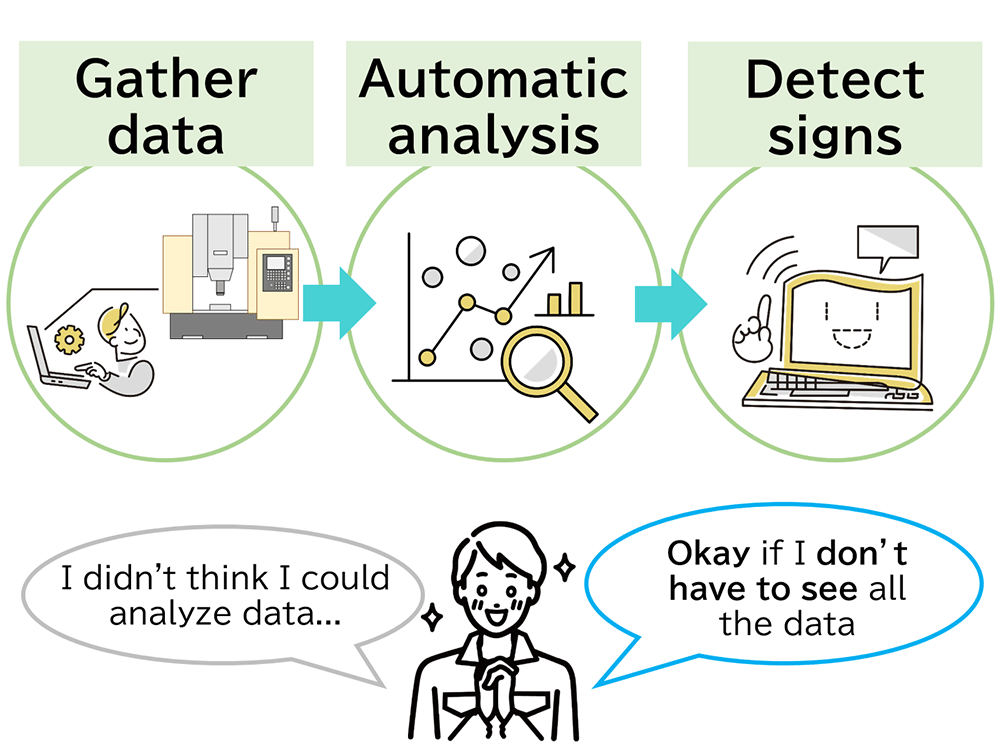

Concept of AI Servo Monitor

No additional sensors or special programs are required. The system measures the speed and torque of the drive axis during regular production operations and automatically detects early signs of failure.

It is easy to start and can be continued without effort, enabling preventive maintenance of equipment.

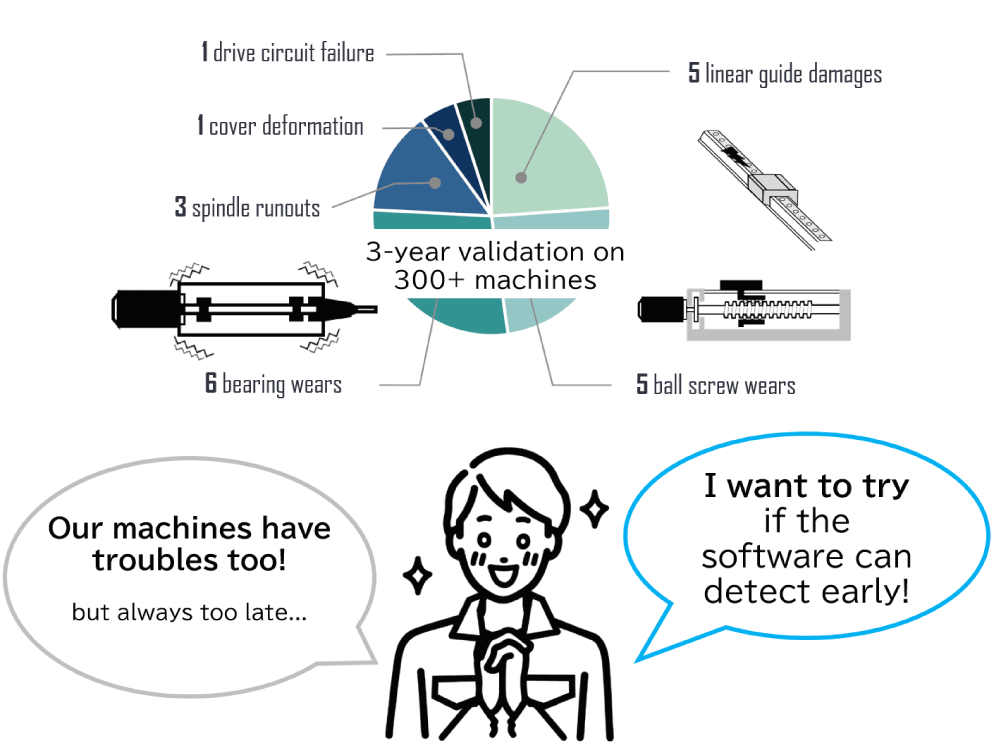

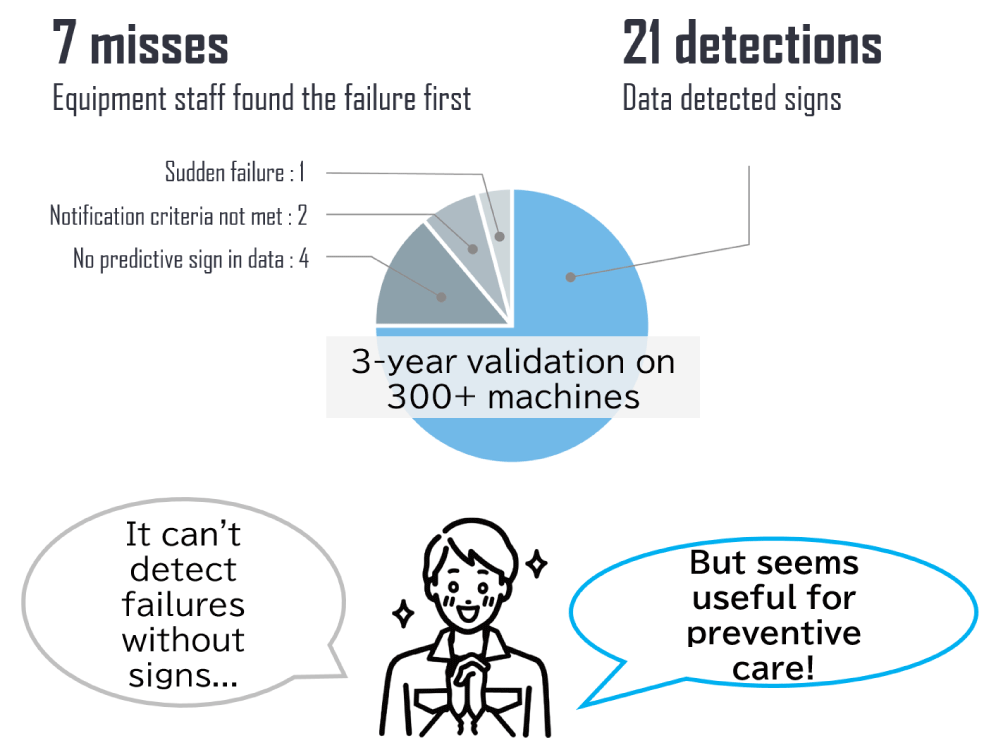

Breakdown of Detected Failures

Over a period of three years, testing was conducted on more than 300 pieces of equipment, resulting in the detection of early signs of failures that could lead to serious equipment shutdowns.

This is the breakdown of 21 early signs of failures detected by the AI Servo Monitor.

Early inspections and repairs were beneficial for the equipment in actual operation.

- Scratches on linear guides

- Wear on ball screws

- Bearing wear

- Increased spindle runout

- Deformation of telescopic covers

- Drive circuit failures

How to Use AI Servo Monitor

Notifies You Before a Breakdown

When a notification of an early sign of failure arrives, perform an inspection of the equipment.

There is no need to check the data every day.

Effective inspections and preventive maintenance aim to extend the lifespan of the equipment.

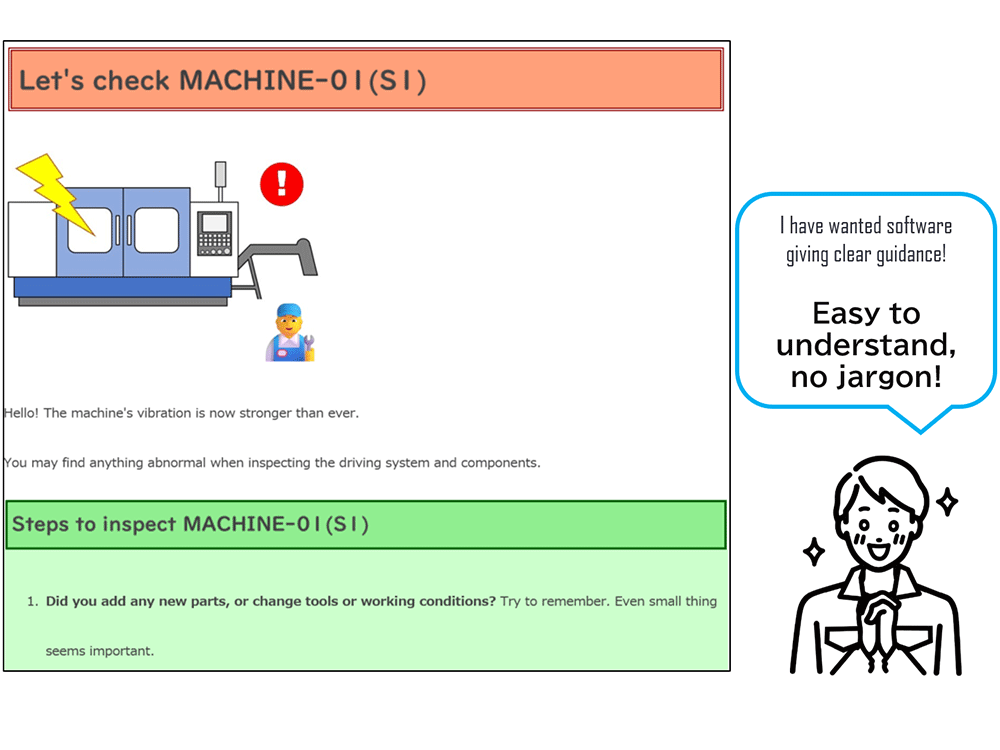

Email Notifications - Understand Early Signs of Failure and Necessary Actions

When an early sign of failure is detected, you will be notified via email.

The email guides you on inspection tasks (visual, auditory, and tactile inspections) and maintenance tasks (cleaning, lubrication, and tightening).

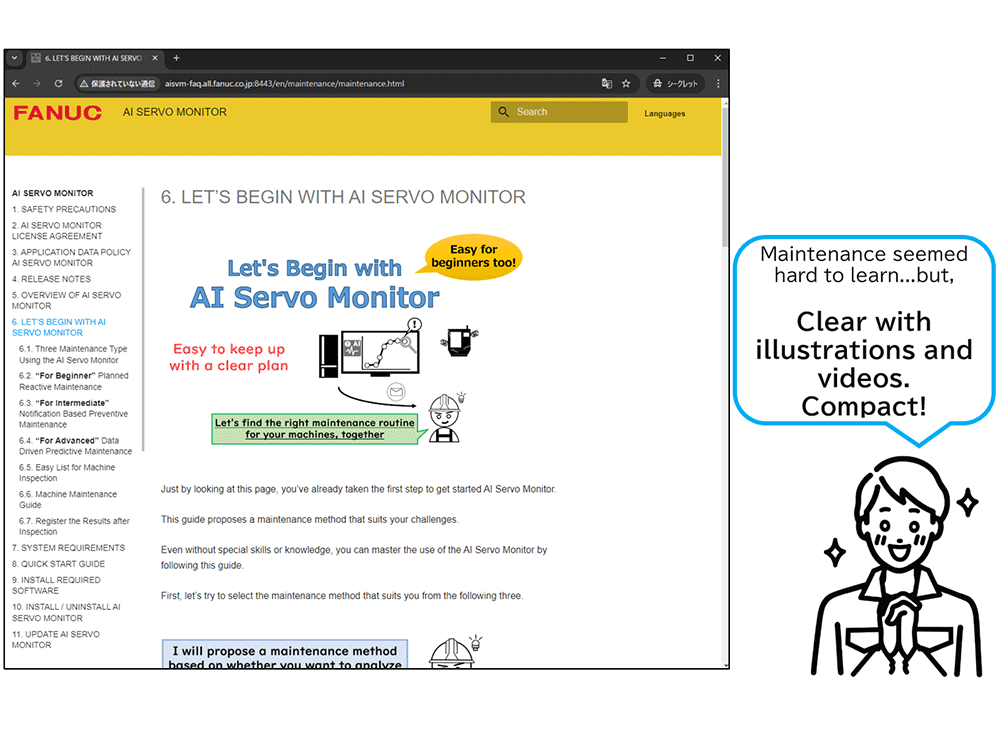

User Manual - Detailed Procedures for Maintenance Tasks

The user manual contains more detailed procedures for inspection and maintenance tasks.

It can be accessed from the email notification, allowing you to quickly find the necessary information for the tasks.

With the user manual, anyone can use the AI Servo Monitor.

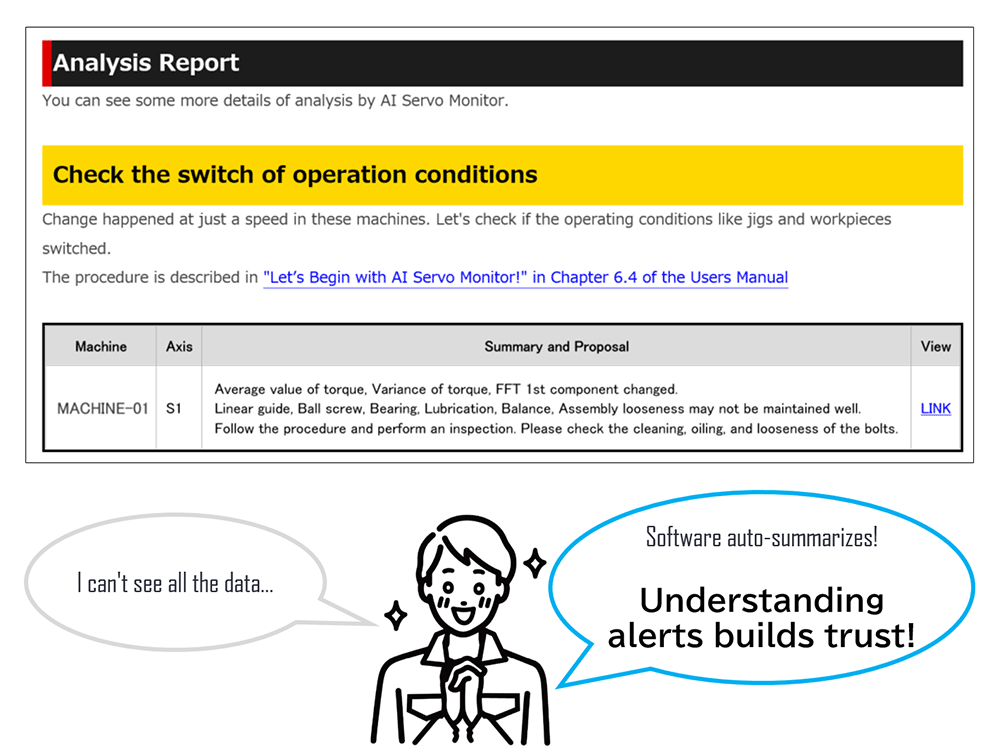

Analysis Report - Understand the Reason for Notifications Without Data Analysis Knowledge

The email notification also includes an analysis report.

There is no need to manually check vast amounts of data; the report explains the reason for the notification.

Limitations of Detection by AI Servo Monitor

While the AI Servo Monitor excels at detecting early signs of failure in motor speed or torque, it may detect failures that do not exhibit these signs or sudden failures

Reasons Why AI Servo Monitor is Easy to Start

Want to Know More About the Benefits of AI Servo Monitor!

- Simple setup and Ongoing ease of use

- No additional sensors are required. You can start by simply connecting the CNC and

computer with a LAN cable.

When early signs of failure are detected, maintenance tasks are notified via email, so there is no need to look at vast amounts of data. - Less Prone to Failure

- You can start small with a familiar off-the-shelf desktop computer instead of a

large-scale system.

Experience the benefits and later add more equipment with additional licenses if needed. - Reliable Maintenance Contract

- AI Servo Monitor comes with a maintenance contract for the first year, ensuring you

can

use it with peace of mind.

Contracts for the second year and beyond are optional and require renewal if you wish to continue. - Single Purchase License with Lifetime Use

- The Single Purchase License with Lifetime Use allows you to use the software without

additional costs, making it ideal for long-term maintenance.

In case the computer is damaged or lost, a reissue of the license will require a fee. - Cost-Effective Maintenance Solutions

- Performing inspection tasks following email notifications of early signs of failure

can

reduce maintenance costs.

Additionally, conducting maintenance tasks such as cleaning, lubrication, and tightening can further reduce long-term maintenance costs.

Want to Know How It Can Be Used for Maintenance!

- Application on the Spindles of Small Machining Centers.

- At production sites for automotive parts and IT equipment, prolonged operating hours

can

lead to spindle damage.

With email notifications from the AI Servo Monitor, you can plan maintenance tasks such as synchronization adjustments at times that do not affect production, thereby extending the equipment's lifespan. - Usage on the Feed Axis of Large Machining Machines

- Large machining machines have drive axes controlled synchronously by two motors.

Over time, desynchronization can occur, leading to potential damage if operations continue unchecked.

Receiving email notifications from AI Servo Monitor, maintenance tasks such as synchronization adjustments can be planned at times that do not affect production, extending the equipment's lifespan.

Equipment Compatible with AI Servo Monitor

Types of Verified Equipment

- Feed axes and spindles of vertical and horizontal machining centers

- Spindles of lathes

Want to Know More About Compatible Equipment!

| Compatible | Not CompatibleNote 1 | |

|---|---|---|

| Current CNC Models | 30i-B, 31i-B, 32i-B, 35i-B, PowerMotioni-A, 0i-F | None |

| Older CNC Models | 16i-B, 18i-B, 21i-B, PowerMate, 30i-A, 31i-A, 32i-A, 0i-D | 16i-A and earlier CNC models |

| Operating Modes | CNC Programs | Control by PMC only, PLC, DSA control, CNC from other manufacturers |

| Program Requirements | Mix of G00 and G01 commands, sufficient dwell for S commandsNote 2 | No mix of G00 and G01 commands, insufficient dwell for S commands |

Comparison with Other Maintenance Software

We have prepared a guide to help you master the AI Servo Monitor.

Compare to find out which one is the easiest to start and continue with.

| FANUC AI Servo Monitor | Measurement Software A for Motors | Cloud Tool B for Machine Parts | |

|---|---|---|---|

| Inspection Guide | Available | Not Available | Not Available |

| Execution of Special Programs | Not Required | Required | Required |

| Additional Sensors | Not Required | Required | Required |

| Purchase Type | One-Time Purchase | One-Time Purchase | Subscription |

How to Start Using AI Servo Monitor

Here are the standard steps to introduce AI Servo Monitor.

Preparation Before Setup

Preparation Before Setup

- 1. Choosing the Target Equipment for Monitoring

- Choose the equipment to be monitored by AI Servo Monitor from your existing equipment. Check the drive axes and usage conditions to determine suitable candidates for installation.

- 2. Acquiring Necessary License

- Purchase the necessary number of basic and additional licenses according to the number of equipment units you want to connect.

- 3. Performing Wiring Connections

- Perform wiring work to connect the CNC and the computer for AI Servo Monitor using LAN cables and installing hubs.

- 4. Verifying Network Connectivity

- After completing the wiring, verify the network connectivity between the CNC and the computer. Use the ping command to ensure communication is functioning correctly.

Installation and Initial Setup

Installation and Initial Setup

- 5. Download the Installer

- Download the AI Servo Monitor installer from FANUC's member site MyFANUC.

- 6. Installation

- Run the downloaded installer to install AI Servo Monitor on your computer. Simply follow the installation wizard to complete the setup.

- 7. License Activation

- After installation, use the license key provided by FANUC to activate the software.

- 8. Register Equipment

- Register the equipment on each of the setup screens for either FIELD system Basic Package or MT-LINKi and for AI ServoMonitor, register the target equipment. Enter the equipment name, IP address, and axes.

- 9. Notification Settings

- Register the internal email server and recipient email addresses to receive notifications of early signs of failure. Start with the default settings for notification frequency and conditions.

- 10. Analysis Calculation Test

- While the equipment is operating, perform an analysis calculation test with AI Servo Monitor. Ensure that measurement data is collected as expected, the analysis calculations are executed, and the number of data entries is not zero. This completes the setup.

AI Servo Monitor Support

With our customer inquiry service, even first-time users can get started with confidence.

We provide a dedicated support desk to handle questions about installation, operation, and any unexpected issues that may arise.

- Support Desk for Installation and Operation

- Support Desk for Troubles and Issues

- Software Update Notification

Frequently Asked Questions

Operational Support & Security (Troubleshooting / Trial Version /

Privacy)

- Suitable Environments for AI Servo Monitor

- It is used for the maintenance of equipment that processes automotive parts, construction machinery, and industrial machinery parts.

- Availability of a Trial Version

- No, there is no trial version available.

- Setting Up Without Advanced IT Skills

- You can set it up by following various guides and the startup manual included with the software.

- Handling Software Issues

- Check the troubleshooting section in the user manual. If the issue cannot be resolved, contact us with the zip file generated by running a specific file and the error message.

- Ensuring Security and Privacy

- Email notifications from AI Servo Monitor are encrypted with SSL/TLS authentication, and data ownership belongs to the purchaser and is not shared with third parties. It can be installed separated from external networks.

Implementation & Initial Operation (Implementation Period /

Post-Notification Operation / Support Details)

- Time Required for Introduction with Multiple Equipment

- It takes about 1 to 3 months. Most of the time is spent on selection and preparation.

- First Steps After Receiving an Email Notification

- Plan your tasks according to the inspection procedures mentioned in the email and the user manual.

- Support Provided for AI Servo Monitor

- Before introduction, we determine applicability. After introduction, we provide support for operational issues.

System Requirements & Required Equipment (PC Requirements / Data

Collection Package)

- Computer Requirements

- A commercially available desktop computer is required. Install it on an SSD of 1TB or more.

- Additional System Requirements

- Besides the AI Servo Monitor, you will need a separate data collection package (FIELD system Basic Package or MT-LINKi, each sold separately).

Functionality & Limitations (Detection Availability / Simultaneous

Monitoring / API Integration)

- Can it identify the broken part of the equipment lifespan?

- No, it cannot identify the broken part or predict the lifespan, but it can detect early signs of drive system failures. Early inspections and planned repairs can help maximize the lifespan of your valuable equipment.

- Can it detect defects in tools or workpieces?

- No, it cannot detect defects in tools or workpieces directly. However, it can find defects in workpieces caused by equipment deterioration.

- Can it monitor all drive axes of the equipment simultaneously?

- No, it cannot monitor all drive axis simultaneously. However, it can monitor multiple axes sequentially by scheduling te measurement times.

- Can it be used for maintaining of equipment that produces a wide variety of products?

- Yes, it can be used for this purpose as it identifies and analyzes machining programs.

- Can it integrate with equipment management systems or core systems?

- Yes, AI Servo Monitor provides a REST API for data integration with equipment management systems (CMMS) or core systems (ERP).

Learn More About AI Servo Monitor

Are you interested in tips and knowledge to avoid failures, from selecting equipment to establishing preventive maintenance?

Feel free to contact us by clicking "Get the Guide".

"AI Servo Monitor" is a registered trademark of FANUC CORPORATION. (No. 6210570)