FANUC ROBONANO α-NTiA

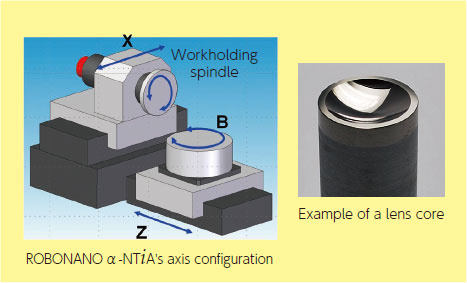

FANUC developed the ROBONANO α-NTiA, a turning version dedicated to ultra-precision machining, as a new model of ROBONANO. It is an ultra-precision machining tool optimal for machining lens cores for cameras installed in IT equipment or automobiles.

Following the launch in 2018 of the ROBONANO α-NMiA, a five-axis machining version, the addition of the turning version to the ROBONANO lineup will make it possible to accommodate a broad range of requirements in the ultraprecision machining market.

Specifications optimal for the turning of lens cores

- FANUC's highly rigid static oil bearings with no solid friction are used in straight two axes (X200 mm × Z200 mm) and the indexing B axis.

- FANUC's aero-static air bearing is used in a workholding spindle. Stability can be retained even in a high-speed rotation of 4,000 min−1.

- A vacuum chuck system is used for high-precision and simple centering and attaching of a lens core. Cores of up to Φ100 mm and 5 kg can be attached.

- An active dumper comes as a standard feature to eliminate the vibration from the floor. With optimization for each user's environment, stability is enhanced in machining.

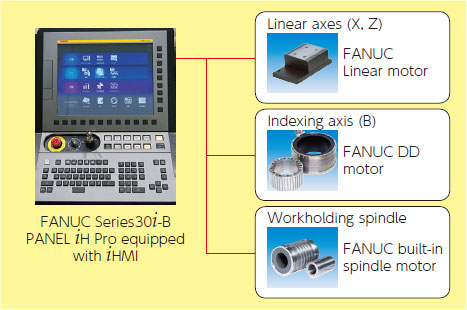

FANUC's standard CNC and motors used

FANUC's standard CNC and motors make servo control highly reliable.

The 0.1 nm program command and HRV4+ enable smoother control than the conventional 1 nm program command (comparison by FANUC).

In combination with FANUC's bearing technology, stable mirror surface turning at a sub-nano level of surface roughness can be achieved.

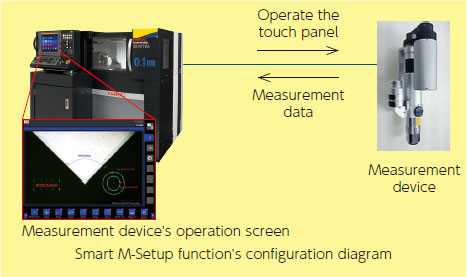

Functions for improving usability

The screen of a measurement device for machining set-up has been added to a dedicated operation screen created with FANUC's Panel iH Pro display unit and iHMI screen.

Set-up of machining is made simple with no need to observe the measurement device, or prepare multiple operation monitors and wiring (function name: Smart M-Setup).

The measurement device can be easily detached or attached since a cabinet is embedded for storing this device.

(FANUC News 2019-III)