New function "Quick and Simple Start-up of Robotization" of ROBOMACHINE

FANUC has developed and launched QSSR (Quick and Simple Start-up of Robotization), which is a package of basic elements required to build robot systems with ROBOMACHINEs.

By using QSSR to build a system, the workload for design and system setup time are significantly reduced, facilitating the installation, setup, and operation of automation systems consisting of ROBOMACHINEs and robots.

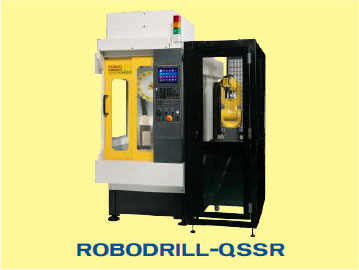

ROBODRILL-QSSR

The ROBODRILL-QSSR, which consists of a compact machining center of the ROBODRILL α-DiB Series and an LR Mate 200iD, is an ideal robot system for automatically changing workpieces.

- Basic elements to build a robot system such as robot installation base, safety fence, easy connection function, and robot sample programs are offered in packaged form for the robotization of machining sites.

- An automatic side door driven with a servo motor can be selected as an option. Compared to the air cylinder driven method, the time for the door to open and close is about 40%, and is much faster. In addition, the load and unload time of workpieces can be significantly reduced by combining with a robot.

![]() Please also see for ROBODRILL-QSSR.

Please also see for ROBODRILL-QSSR.

ROBOSHOT-QSSR

The ROBOSHOT-QSSR, which consists of an electric injection molding machine of the ROBOSHOT α-SiA Series and an LR Mate 200iD, is a robot system that is ideal for unloading molded parts and assembly after molding.

- Basic elements to build a robot system such as a robot installation base, safety fence, safety mechanism, and robot sample programs are offered in a packaged form for the robotization of molding sites.

- Customization of robot operations is possible by adding information to a preinstalled robot sample program. The information teaches proper positions for the application.

ROBOCUT-QSSR

The ROBOCUT-QSSR, which consists of a wire electrical discharge machine of the ROBOCUT α-CiB Series and an M-20iA, is an optimal robot system for the automatic exchange of machining workpieces to be machined.

- Basic elements to build a robot system such as a robot installation base, safety fence, safety mechanism, and robot sample programs are offered in a packaged form for the robotization of machining sites.

- The core stitch function temporarily adheres cores that must be removed after rough cutting to workpieces. Then the robot removes the cores before finishing. This function and the automatic workpiece exchanging functionenables continuous unmanned operation for long periods of time.

(FANUC News 2020-I)