FA New product: αi-D series SERVO

To respond to changes in the business environment of machine tools, FANUC αi-D series SERVO has been released, which features completely new motors, amplifiers, and servo control software. In addition to higher performance as a servo system that can respond to changes in machining technology, αi-D series SERVO is a new generation servo system that is easier to use with its compact size and less wiring, as well as contributes to energy saving of machines by reducing loss.

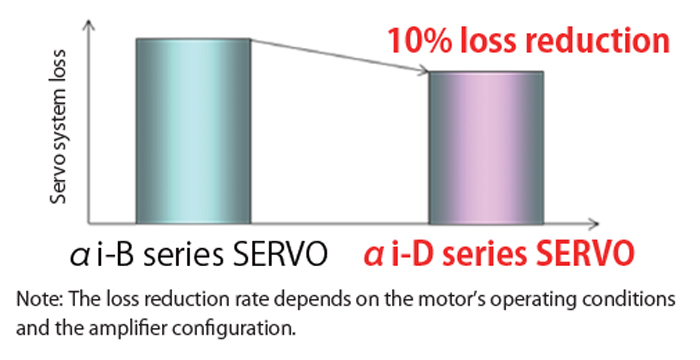

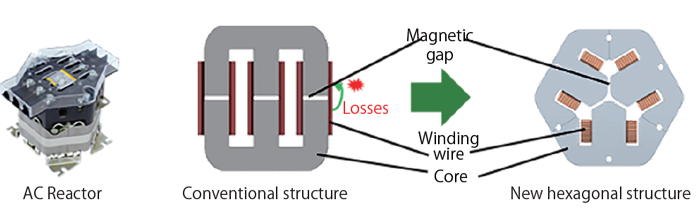

Energy Saving Performance of the Entire System

αi-D series SERVO system reduces overall losses by approximately 10% compared with our former series. This is made possible through its highly efficient motors and current control, state-of-the-art power devices, and unique low-loss AC reactors. As for large servo motors, which are used in servo presses among others, motor power loss is approximately 30% less than before.

Servo Motor

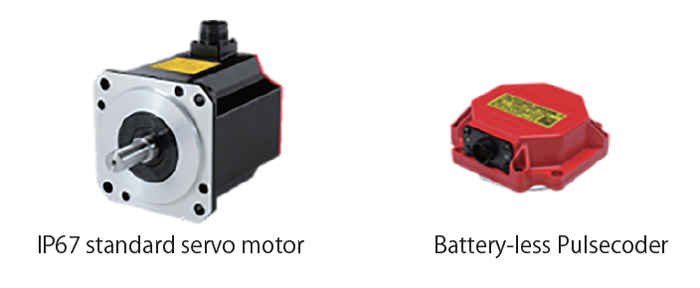

SERVO MOTOR αi-D series has better maximum torque characteristics and maximum rotational speed which reduce cycle time of machining. The battery-less Pulsecoder is selectable for all motor models, and the protection degree of servo motors has been upgraded to IP67 as standard. Thus, maintainability and reliability are enhanced.

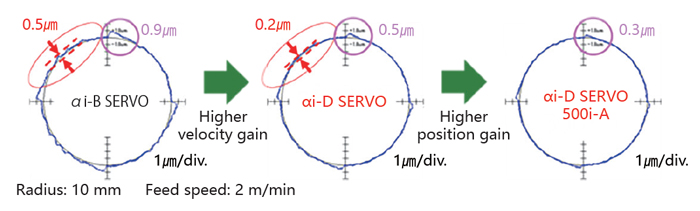

Cogging torque, that is uneven torque created by the magnetic attractive force between magnets on the rotor and the iron core, has been further reduced, resulting in smoother axis feed. In addition, faster communication speed of the Pulsecoder (rotary encoder) enables higher gain control with higher responsiveness. In the example below, by using αi-D series SERVO, the velocity loop gain can be increased and the shape error and the position deviation, when rotational direction of a motor is reversed, can be decreased by about half. In combination with FANUC Series 500i-A, moreover, higher precision and higher quality machining can be possible.

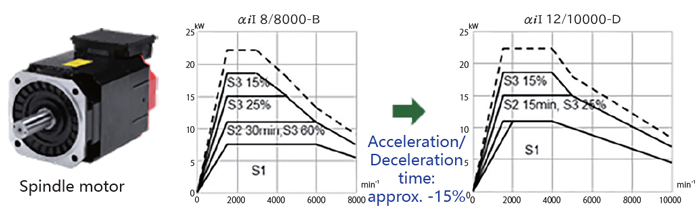

Spindle Motor

The increased acceleration/deceleration power enables shorter cycle time, and the increased continuous power and maximum rotational speed boosts machining performance. The vibration level of the standard models has been improved, making machining more accurate.

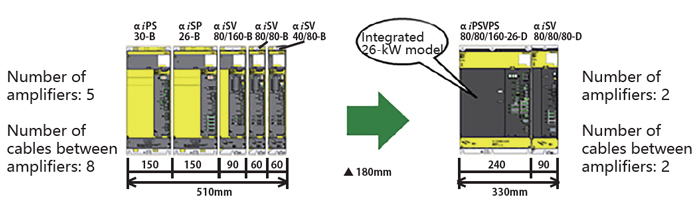

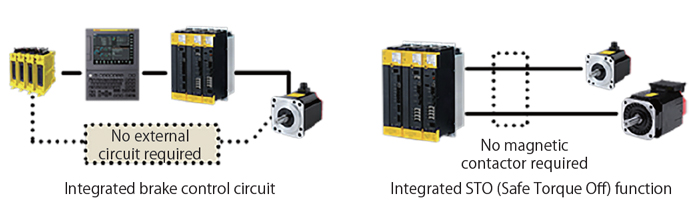

Servo Amplifier

The width of the amplifiers has been reduced by up to 30% and it contributes to downsizing of a control cabinet. The lineup of the all-in-one type amplifiers has been expanded up to 26kW models to meet various machine configuration. The brake control circuit has been incorporated in all servo amplifiers and, especially in combination with FANUC Series 500i-A, STO (Safe Torque Off) function is available without conventional external wirings. This reduces the number of wiring and improves ease of use.

For failure prediction, the insulation deterioration detection function has been incorporated in all amplifiers including all-in-one type, which enables preventive maintenance. For maintainability, the structure has been designed to allow the fan motor to be replaced without removing the DC-link short bars, while the amplifier is kept mounted on the control cabinet, thus reducing replacement time.

AC Reactor

The new AC reactor has been designed with the unique hexagonal structure and reduces losses due to leakage flux, thereby contributing energy saving.

(January 2024)