Performance in FY2023

Amount of Electric Power Used

Actual Reduction in the Amount of Electric Power Used

As part of our efforts to reduce our output of greenhouse gases such as CO2 and thus prevent global warming, we are constantly aiming to reduce the amount of electric power that we use.

The power used in proportion to the level of production in FY2023 increased by 7.4% compared to the previous fiscal year’s level, and we could achieve the FY2023 target.

Electric Power Reduction Measures (main measures implemented by FY2023)

- Some machine tools in our plants were exchanged for those incorporating auto power-off devices.

- Some of the compressors in our plants were exchanged for those incorporating inverter controls.

- Energy-saving fluorescent lamps (with electronic ballasts) and energy-saving compressors (inverter type) were installed in new buildings.

- The roofs of new buildings were changed to silver in color.

- The roofs of new buildings were enhanced in heat insulation by duplicating them.

- Power consumption was reduced with motion sensors.

- Wind-shielding curtains were used for energy saving in air conditioning.

- Measures were taken against heat emissions from compressors for energy saving.

- Energy-saving measures were studied by energy-saving consultants.

- Use of LED lighting was promoted.

- Co-generation was promoted.

- Power waste was reduced by preventing leakage of compressed air piping.

- Solar panels were installed.

- Reduction in the number of compressors.

Amount of Kerosene/LPG Used

Kerosene/LPG Reduction Results (main measures implemented by FY2023)

In some parts of the Tsukuba factory, kerosene was replaced by city gas.

In conjunction with the shift of fuel for boilers from kerosene to city gas, we removed underground tanks, which reduced the burden of legal management of the tanks under the Fire Service Act and contributed to the reduction of environmental burden such as water pollution and soil pollution through avoiding leakage of kerosene when receiving it from a kerosene truck.

Amount of Waste Liquid Discarded and Amounts of Other Waste

Waste Liquid Reduction Results

Identified the actual amount of waste liquid discarded in FY2023 in proportion to the level of production. Improved the management of waste liquid, so as to prevent environmental pollution due to spilled waste liquid.

Waste Liquid Reduction Measures (main measures implemented by FY2023)

- Reused separated water by introducing oil-water separators

- Collected cutting fluid attached to chips and reused it.

- Used mold release materials with less amount of waste liquid.

- Used long-life cutting fluid.

- Reused distilled water by deploying distillation and regenerating equipment.

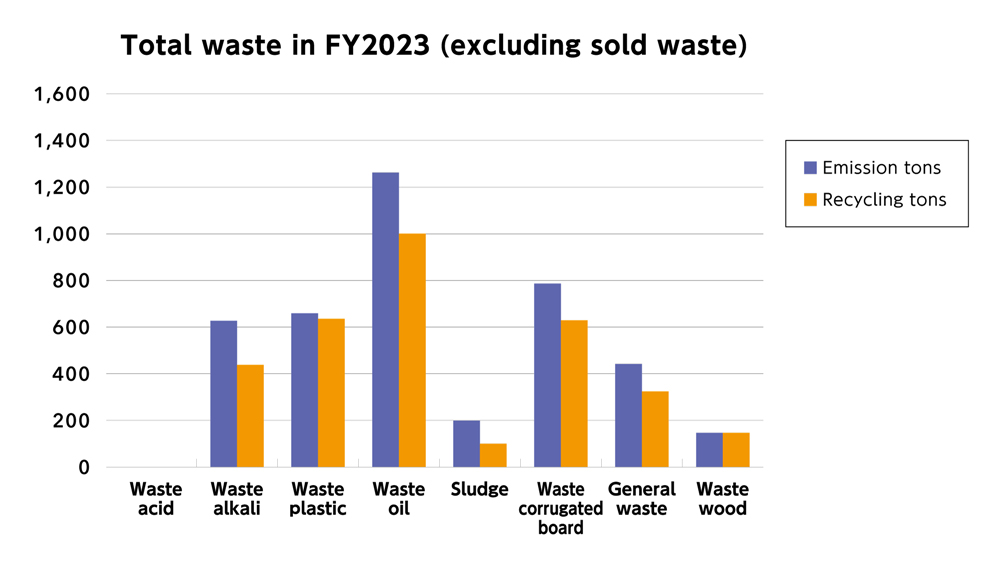

Other Waste

Almost all waste was recycled.

We sold waste metal 21,571(t), waste plastic 54(t), and waste liquid 50(t) for recycling.

Amount of Chemical (PRTR) Substances Used

PRTR Chemical Substance Reduction Results

Identified the actual amount of PRTR chemical substances used for production in FY2023 in proportion to the level of production.

Improved the management of chemical substances, so as to prevent environmental pollution due to spilled chemical substances.

PRTR Chemical Substance Reduction Measures (measures implemented by FY2023)

- Used cutting fluid that does not contain N, N-Dicyclohexylamine.

- Replaced HCFC 141b with other materials.

- Used oil not containing xylene.

- Banned the use of copper salts.

- Banned the use of ferric chloride.

- Used lead-free solder.

- Used coating material containing no ethylbenzene.

- From HCFC-225 to HCFO type (ozone depletion factor is almost zero, global warming potential is less than one, not subject to PRTR)

- Products containing ethylene glycol monoethyl acetate (Manufacture 9) changed to non-PRTR products

Total Chemical Substance Control

In order to implement the total field control of objects stored by divisions using chemical substances, we conducted the following inspections and remedied those defects found as a result of those inspections:

- Entry of stored objects into the ledger

- Name indication

- Maximum quantity of dangerous objects that can be held in the storehouse

- Whether storage containers are free from damage and leakage.

- Whether periodic inspections are conducted.

- Whether protective devices are provided.

We also conducted an emergency drill assuming chemical substance leakage.

Development of Environmentally Friendly Products

The research and development divisions evaluate the environmental impact of products, set targets and develop environmentally friendly products.

The Product Development Subcommittee under the environmental management system prepares environmental management plans, and product developments are conducted based on medium- to long-term plans and annual plans.

| CNC System |

|

|---|---|

| LASER |

|

| ROBOT |

|

| ROBODRILL |

|

| ROBOSHOT |

|

| ROBOCUT |

|