Disclosure in Accordance with TCFD Recommendations

Since the adoption at COP21 (21st Conference of the Parties to the United Nations Framework Convention on Climate Change) of the Paris Agreement, movement towards a de-carbonized society is spreading. FANUC Group with its business activities expanding around the world promotes these initiatives as we recognize climate change as a critical business challenge.

In the meantime, FANUC expressed its support for the Task-Force on Climate-related Financial Disclosures and its recommendations (hereafter, TCFD recommendations) in December 2021.

Further, we would like to utilize the framework of TCFD recommendations, and continue enhancing the quality and amount of disclosures to promote climate change initiatives still further, and contribute to achieving a sustainable society.

Governance

FANUC recognizes climate change as a critical business challenge.

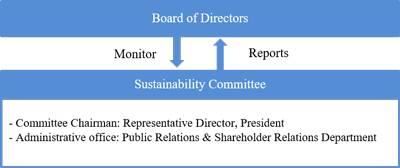

At the “Sustainability Committee” chaired by the Representative Director, President, we will deliberate and make decisions on important policies and measures related to climate change, and report to the Board of Directors. Based on the reported content, the Board of Directors will supervise to check whether identification of risks and opportunities, and measures related to climate change are promoted appropriately.

Strategy

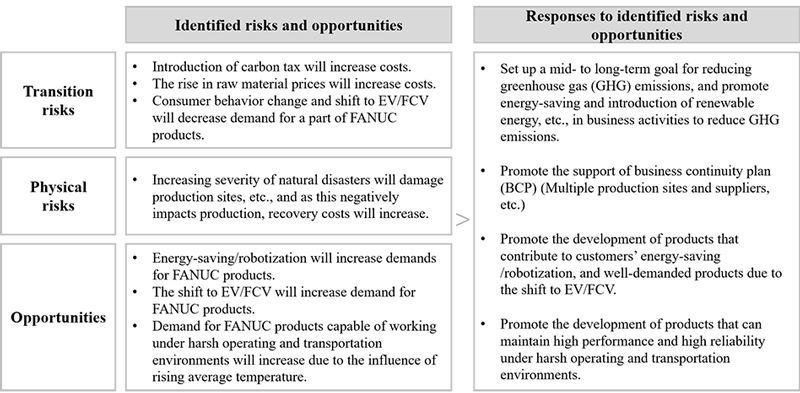

FANUC conducted a scenario analysis targeting mid-term (2030) and long-term (2050) with a 1.5°C scenario, 2°C scenario, and 4°C scenario on the FA business, Robot business, and Robomachine business to identify the risks and opportunities related to climate change, and to check how these will impact FANUC Group businesses. Regarding the scenario analysis, we referred to IEA NZE, IPCC RCP1.9, etc., for 1.5°C, IEA SDS, IPCC RCP2.6, etc., for 2°C, and IEA STEPS, IPCC RCP8.5, etc., for 4°C. For each scenario, we identified the risks and opportunities related to climate change, and quantitatively and qualitatively examined and evaluated the impact on the business.

Among these, we identified the following risks that will have a significant impact on the businesses: “Increase in costs due to introduction of carbon tax,” “Increase in costs due to the rise in raw material prices,” and “Decrease in demand for a part of FANUC products due to the consumer behavior change and shift to EV⁄FCV”. We also identified the following opportunities: “Increase in demands for FANUC products due to energy-saving and robotization,” and “Increase in demands for FANUC products due to the shift to EV⁄FCV.”

In the 1.5°C and 2°C scenario, the world is expected to undergo major social changes as it transitions to de-carbonization. There is a possibility for costs to increase due to the introduction of carbon taxes and rise in raw material prices, but we believe that we can expand the FA business, Robot business, and Robomachine business as energy-saving⁄robotization, and that the shift to EV⁄FCV will expand. The 4°C scenario does not promote low carbonization, and increasing severity of natural disasters will be expected due to climate change, such as increases in average temperature. This creates a potential increase in recovery costs as production sites, etc., will be damaged, having a negative impact on production. For these reasons, we will continue to promote the support of our business continuity plan (BCP), and deal with physical risks.

The findings of the scenario analysis on FA business, Robot business and Robomachine business rated these businesses as highly resilient in all scenarios used for the analysis. We will further promote initiatives in order to meet the challenges of identified risks and realize these opportunities in the future.

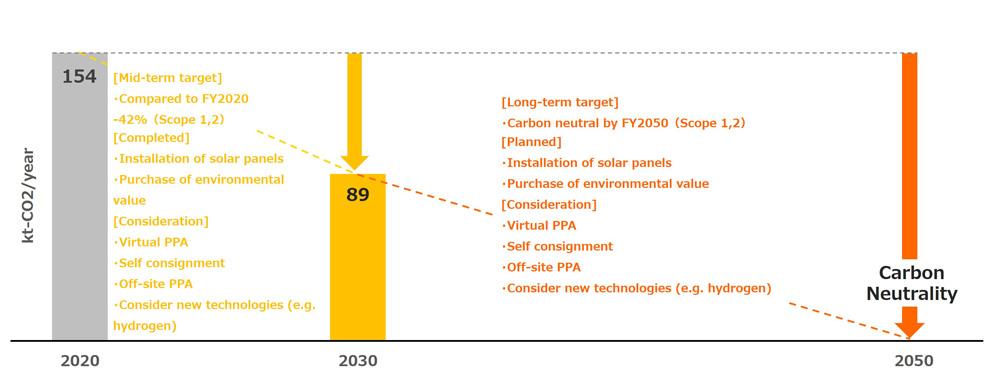

Roadmap to carbon neutrality

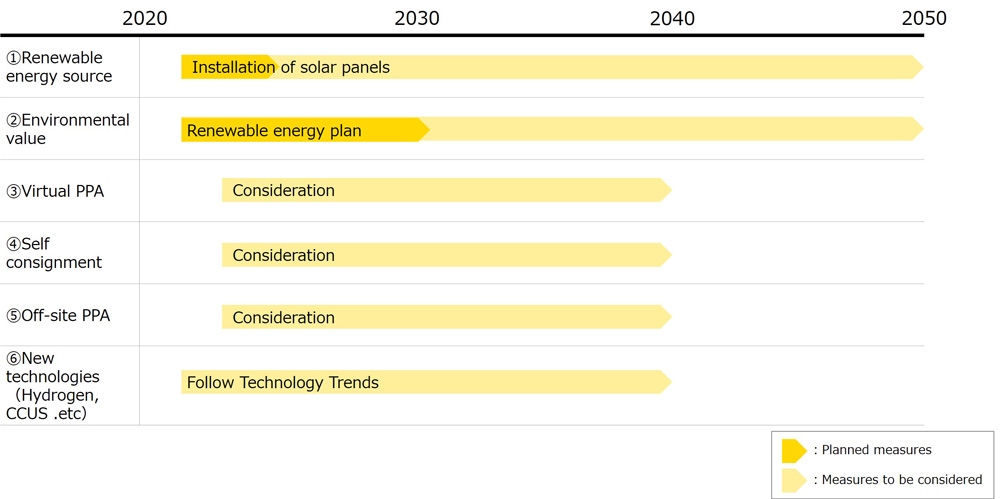

FANUC has set a mid-term goal (certified by the SBT initiative) to reduce its Scope 1,2 emissions by 42% from FY 2020 level by 2030, and is promoting efforts to achieve this goal.

Toward this goal, we plan to install solar panels and renewable electricity, and expect to invest approximately 9 billion yen. (Amounts are subject to uncertainties and assumptions and may differ from actual results.)

Risk Management

To address risks that may hinder the continuity of our business, the enhancement of our corporate value, or the sustainable development of our corporate activities, FANUC has established a Risk Management Committee and risk management policies, and we are conducting appropriate risk management under the supervision of the Board of Directors. The risks of climate change will also be placed in the rules, and managed.

Metrics and Targets

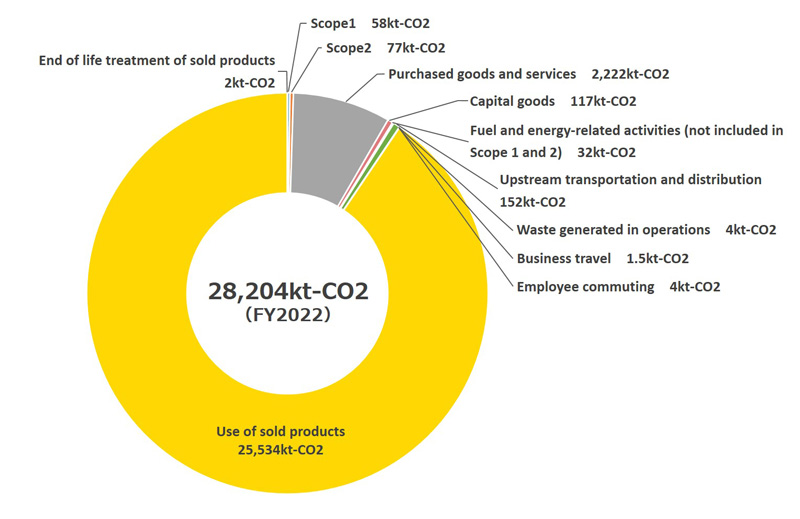

The FANUC Group’s greenhouse gas (GHG) emissions (Scope 1, 2 and 3 Category11) targets and results are as follows:

| FY2020 Results (Base Year) | FY2023 Results (In comparison with FY2020) | 2030 Targets (In comparison with FY2020) | 2050 Targets | |

|---|---|---|---|---|

| Scope1 and 2 | 154 kt-CO2 | 126 kt-CO2(-18.5%) | -42% | Zero |

| Scope3 Category11 | 16,668 kt-CO2 | 15,324 kt-CO2(-8.1%) | -12.3% | - |

*Regarding the third-party verification report on GHG emissions (Scope 1, 2 and 3), please see here.

FANUC has set up a long-term target of reducing GHG emissions from the business activities of FANUC Group (Scope 1, 2) to zero by FY2050. To achieve this long-term target, we have set a mid-term target of 42% reduction of the same emissions by FY2030 (in comparison with FY2020). Regarding Scope 3, we aim for 12.3% reduction of emissions due to the use of sold products(Category 11) by FY2030 (in comparison with FY2020). These mid-term targets are certified by the SBT (Science Based Targets) initiative.

Scope 1 and 2 for FY2023 were 18.5% lower than the base year.

The main reason is that a part of the electricity used in the Headquarters area, the Mibu Factories, Tsukuba Factories, etc. was switched to electricity derived from renewable energy sources. In FY2022 and FY2023, solar panels are being installed in the Head Office and Mibu area, which is expected to further reduce emissions in FY2024 and beyond.

In FY2023, emissions due to the use of sold products for Scope 3 (Category 11) were 8.1% lesser than the base year. This was mainly due to a decrease in the sales of our products. We will continue to aim for emission reductions by further improving the energy-saving performance of our FA, ROBOT, and ROBOMACHINE products.