Service

Lifetime Maintenance

FANUC provides lifetime maintenance for its products as long as they are used by customers, even for models that are no longer in production. Lifetime maintenance makes it unnecessary for our customers to renew their equipment due to discontinued maintenance service, thereby allowing them to use FANUC products at a low cost for several decades.

At our Repair Factory, we perform approximately 80,000 repairs per year in Japan, including products that were manufactured more than 40 years ago. We have a stock of over 3.5 million pieces of 19,000 types of repair parts, including old parts that are no longer in production, ready to repair used motors, PCBs, or units.

Even in cases where some parts run out of stock, the Repair Factory has a system for finding replacement substitutes or redesigning them. In addition, old manuals are also digitized as part of our efforts for lifetime maintenance.

Units which have broken down are cleaned in an automatic washing machine using robots or other means, and after drying them overnight with a drying furnace, they are repaired. Not only damaged parts, but also parts that are starting to deteriorate are replaced, to attain a quality in repair that is equal to a brand new unit.

We collect parts that have deteriorated but can still be regenerated and overhaul them for re-use, thus contributing to the reduction of waste as well.

The Repair Factory has performed over 2.4 million repairs thus far, and its know-how is utilized in domestic and overseas repairs, as well as being fed back to laboratories.

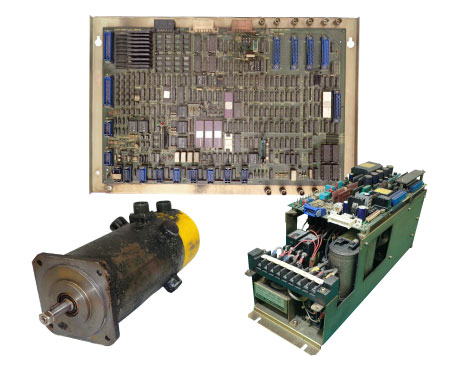

Example of repair for PCB, spindle motor and servo amplifier unit over 40 years ago.

Before repair

After repair

Providing Global Services

Based on the spirit of “Service First”, FANUC provides lifetime maintenance for its products for as long as they are used by customers, through more than 270 service locations supporting more than 100 countries throughout the world.

Basic Approach

Based on our spirit of “Service First”, FANUC strives to improve customer satisfaction by providing prompt and careful services and lifetime maintenance.

Policy

Conforming to the spirit of “Service First”, FANUC provides lifetime maintenance to its products for as long as they are used by customers, through service locations near customers throughout the world.

Promotion Framework

Once a year, we hold the Global Service Conference, organized by the Representative Director, President and CEO, which is attended by top management of Group companies and service personnel from locations around the world, as well as key members from FANUC Headquarters.

From 2020 to 2022, due to the Covid-19 pandemic, we used online discussion boards to hold conferences, and just as in real conferences, participants share case studies and knowledge about topics like parts and technical information, maintenance tools, service training, and service DX through various working group activities to improve and strengthen our services.

In the 2023 Global Service Conference, we held a non-virtual meeting attended by a total of 454 participants with lively discussions at the headquarters for the first time in four years.

Goals

We aim to improve customer satisfaction by providing better services. To this end, we make efforts to shorten the average waiting time for services, and increase the percentage of maintenance parts that can be delivered immediately on demand.

Initiatives

To Realize Mobile Services

More than 2,300 service personnel and support staff (all are FANUC Group employees) around the world handle phone calls, provide services at customer sites, and manage maintenance parts. Units replaced at the request of our customers are repaired at Repair Factories in 14 locations around the world to be reused. Using these units in subsequent maintenance services leads to waste reduction and the effective utilization of resources.

In our domestic services, we are striving to enhance mobility, primarily by having all field service personnel carry a mobile device, so that representatives can visit customer sites as quickly as possible, based on the current locations of all personnel.

To further reduce wait times, we do not divide the introductory training into groups by machine type for new hires after 2021. Instead, all new hires receive the same training.

Younger employees who joined the company before that time also receive cross-training, not just on the machines with which they are proficient. We focus on training multi-skilled service personnel who can handle all types of products including FA (CNC), LASER, ROBOT, and ROBOMACHINE, thereby enabling flexible response and efficient dispatch and shortening travel distance and time.

The realization of flexible services requires all types of maintenance parts that amount to an enormous quantity.

FANUC has a global parts warehouse in Japan to store maintenance parts for which there is extremely low demand. We also strive to visualize inventory around the world.

Even parts that are used extremely rarely are stored somewhere in our global service network, and by managing this information, we are able to provide parts in the shortest possible time. Inventory data is updated to provide parts as quickly as possible. In addition, we prepare an overall demand forecast for maintenance parts, in order to utilize the data to streamline the supply of parts.

Furthermore, we established additional core locations in Japan as part of our business continuity plan (BCP), to secure the continuity of our services. We have also ensured that we can continue providing lifetime maintenance by establishing call centers and parts warehouses in the two locations of Hino, Tokyo and Komaki, Aichi, as well as by installing in both of the locations and mirroring the servers that contain accumulated information, including past service data.

In addition, the Yamanashi (formerly Chuo), Mikawa (formerly Anjo) and Kokura Service Centers were relocated to new buildings, and these service centers, which have expanded floor space, began operations between 2023 and 2024. The parts warehouse within the service centers has also been expanded, and by increasing the parts inventory, the number of cases that can be handled in response to urgent requests from customers has increased.

Furthermore, we have also set up overhaul facilities at the above three locations, which were previously only available in Nagoya and Hino. This allows us to better respond to requests from customers for the collection and overhaul of various types of machinery and robots.

Nagoya Service Center

Hino Branch Office

Enhancing Our Service System

In our after‒sales service, in addition to carrying out repairs in a short time, we are strengthening our efforts to implement preventive maintenance by detecting signs of trouble before breakdowns. We actively propose and sell AI Servo Monitor, which connects CNCs via a network and collects servo data to predict failures, and ZDT (Zero Downtime), which connects robots via a network and centrally manages information on mechanical parts, processes, system status, and maintenance timing to monitor information and perform preventive maintenance.

In addition, we are encouraging preventive maintenance in order to improve operating rates in our customers' factories. In our call centers, we accept inquiries regarding repairs in case of failures and parts sales.

We have established a toll-free line in Japan to respond to inquiries. Call centers use a dedicated reception software which are updated as needed, reflecting requests from service personnel and operators.

Similar software is used in our overseas offices tailored to the circumstances and characteristics of each country.

Key data from individual maintenance reports is shared among countries, and utilized primarily to improve reliability, and develop jigs and tools.

To accommodate the new normal era created by COVID-19, we are pursuing new types of services, such as remote diagnosis and online support, as a project for service DX.

Our first step was to launch FabriQR Contact, a contact service using 2D codes, in Japan in October 2020. We have also started operating overseas from April 2024.

Services in Japan

We accept calls until 5:10 p.m. on Saturdays for customers who operate their factories on weekends.

After long public holidays and other times when there is a heavy concentration of calls, all staff in each location, including veteran field engineers, handle calls, and calls are automatically forwarded from the call center to available lines at locations to prevent a fall in response rate.

We also provide the CS24 service (for a fee) to customers who request availability at night and on Sundays and holidays.

Some overseas offices have individual contracts with customers to provide maintenance services 24/7.

In addition, we provide a maintenance contracts after expiration of the warranty period. Customers who have signed the contract to prepare for any product failures after the warranty period expires, are entitled to repair services which are free of charge within the contract term for an unlimited number of times (some parts and supplies are excluded).

Membership Website

A membership website established in April 2015 provides downloads of electronic data for outline drawings to members free of charge. There are two types of membership, i.e., general membership open to the general public amounting to around 8,738 members, and customer membership limited to actual users of FANUC products currently consisting of around 11,365 members (as of July 1, 2024).

Customer membership website is a very convenient site where a customer can download materials including electronic manuals and purchase maintenance parts.

In December 2019, we added a chatbot function, launching a Q&A service regarding the membership website.

We have also begun responding to customer members’ technical inquiries with the use of a chatbot function. We are engaged in initiatives to enhance convenience for customer members by regularly adding and updating Q&A content.

The membership website was updated to “MyFANUC” on the new platform in August 2023. The conventional maintenance service related functions have also been transferred to MyFANUC and can be used there in the same way as before. In addition, we have released E-Store that sells 10,000 parts, the number of which was increased from 150 to enhance convenience of the maintenance parts sales site. We will improve contents to provide going forward.

![]() Membership Website (in Japanese)

Membership Website (in Japanese)

*Japanese site services are available only in Japan.

Customer Satisfaction Surveys

FANUC America, FANUC Europe, and other overseas group companies conduct regular customer satisfaction surveys. In Japan, we conduct anonymous questionnaire surveys of customers that we attend on site, in order to reflect customer feedback in improvements to our services.

In a customer satisfaction survey conducted in Japan in 2023, we received a score of 4.48 out of 5, up from the previous year's average of 4.31. The score for the clarity of the instructions and help documents increased from 4.02 to 4.38. On the other hand, the score of 4.08 for the ease of reaching the call center has not improved. It appears that customers are dissatisfied not only with the time it takes to get through on the first call, but also with the time it takes to speak with an engineer. We will continue to review the number of engineers and how to respond more efficiently.

Support for Restoration from Natural Disaster

Many natural disasters occur in Japan every year, and we dispatch service personnel to respond according to the needs of our customers.

In 2022, there were no large natural disasters, but floods occurred in some regions. We visited those regions before restoration of power to make efforts to minimize our customers’ machine downtime by promptly washing, drying, replacing parts and conducting level adjustment and replacing parts damaged due to earthquakes.

Overseas, FANUC India, FANUC Indonesia, FANUC Thailand, and FANUC South America have worked to restore operations as quickly as possible by arranging parts and providing repairs at repair shops in response to flooding in India, Indonesia, Thailand, and Brazil.

FANUC responds to disasters under our philosophies of “one FANUC”, “Reliable, Predictable, Easy to Repair”, and “Service First”.