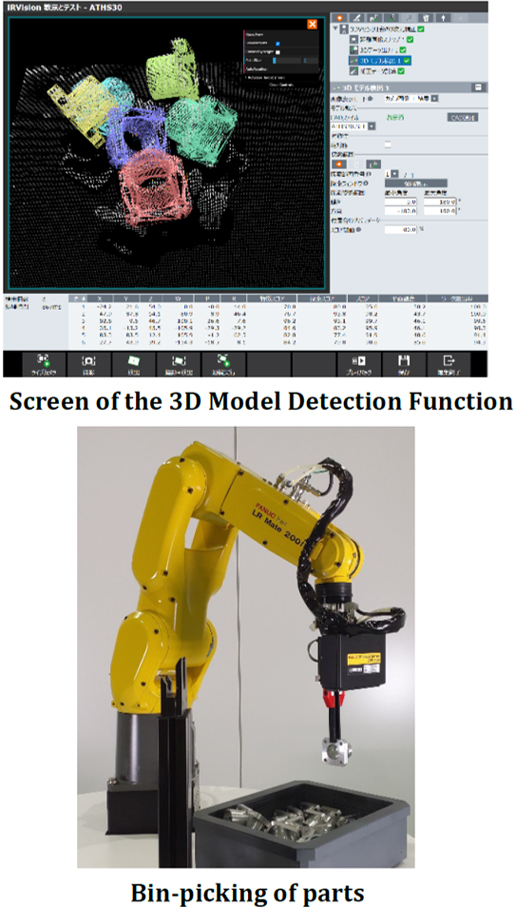

ROBOT New Function: iRVision 3D Model Detection Function

FANUC has developed the 3D Model Detection Function, which easily captures the characteristics of a part from its 3D CAD data and uses vision to detect the part. It can be applied to a system in which a robot picks up one of many parts placed randomly in a returnable container, by using a 3D vision sensor.

- This function automatically generates the settings for detecting a part in various positions from the part’s 3D CAD data.

- Previously, it was necessary to manually make the settings for a robot to detect a part in each possible position and register the settings one by one. This function automates the work of making and registering the detection settings to facilitate the startup of a bin-picking system.

- The part detection processing is performed by PANEL iH Pro, which has high processing power and connects to a robot controller via an Ethernet cable. This configuration has improved the detection capability, reduced the detection time, and has made it easier for FANUC to provide lifetime maintenance.

FANUC will continue to improve the vision functions that serve as the “eyes of robots” to contribute to automation in production sites.

(FANUC News 2021-I)